CN Household Pipe Fittings Manufacturing Group

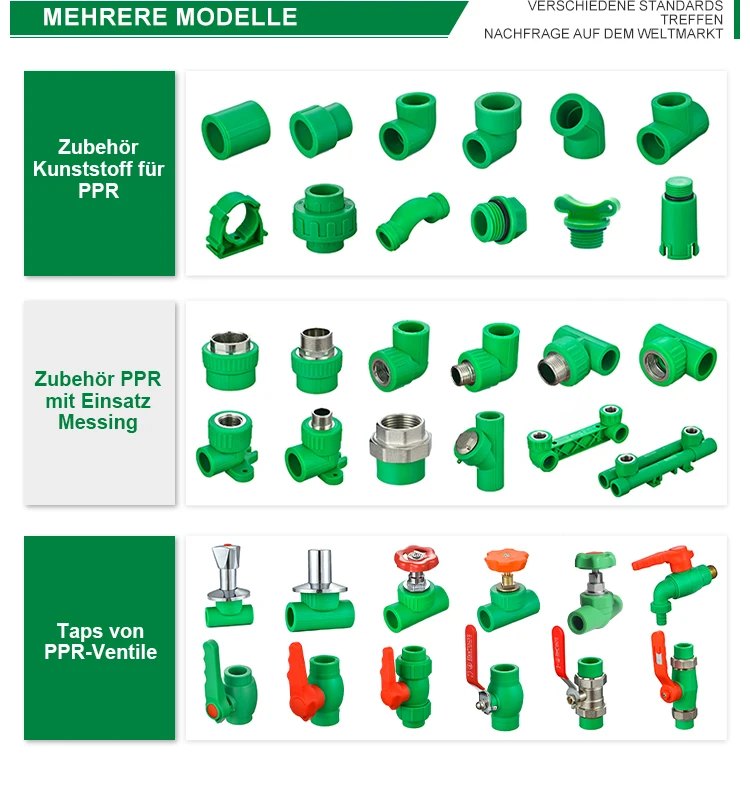

Produktname: PPR-Rohrverbindungen

Material: Korea Hyosung-Rohmaterial

Farbe: Grün/Weiß/Gelb/Grau/Blau/Kundenspezifisch

Größe: 20–110 mm

Verpackung: Opp-Beutel + Karton oder kundenspezifisch

Verbindung: Schweißen

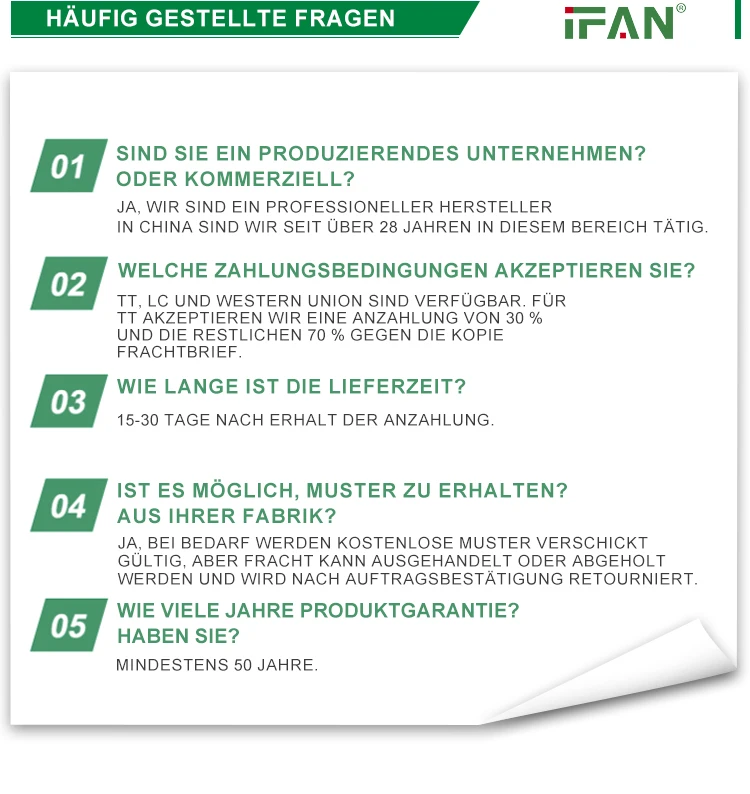

Garantiezeit: 50 Jahre

Lieferhafen: Ningbo, Yiwu, Shanghai

Muster: Kontaktieren Sie uns für ein kostenloses Muster

Senden Sie das Formular, um sofort eine Produktpreisliste und kostenlose Muster zu erhalten

PPR pipes handle various temperatures, but extreme heat affects durability. Proper maintenance ensures long-term performance. PPR-Rohrschelle stabilises pipes, reducing stress from temperature changes.

High temperatures cause expansion and contraction. Without support, pipes deform or crack. Secure mounting with PPR-Rohrschelle prevents excessive movement. Regular inspections help detect heat-related damage early.

Selecting quality materials extends the lifespan of PPR pipes. PPR-Rohrschelle must withstand high temperatures without losing strength. Low-quality materials degrade faster, causing leaks or structural issues.

Certified PPR products ensure better thermal resistance. Heat-resistant coatings provide additional protection. Using durable materials reduces maintenance costs and prevents frequent replacements.

Correct installation protects PPR pipes from thermal stress. PPR-Rohrschelle must be placed at regular intervals to support pipe structure. Poor installation weakens joints and increases failure risks.

Thermal expansion gaps prevent excessive pressure on connections. Following manufacturer guidelines ensures long-lasting performance. Skilled professionals should handle installation to avoid common errors.

Extreme heat softens PPR material, leading to deformation. PPR-Rohrschelle holds pipes in position, preventing sagging or bending. Insulating pipes reduces direct heat exposure and minimises expansion effects.

Regulating water temperature prevents unnecessary stress. Avoiding sudden temperature changes protects the entire piping system. Consistent maintenance ensures stability under varying thermal conditions.

Routine inspections help identify early signs of heat-related wear. Checking PPR-Rohrschelle for cracks or looseness prevents major failures. Small damages worsen over time if ignored.

Pressure testing detects weaknesses in high-temperature conditions. Thermal imaging helps monitor heat distribution. Early repairs prevent costly replacements and system inefficiencies.

Dirt and mineral deposits reduce heat resistance. Cleaning PPR-Rohrschelle and pipes removes build-up, ensuring efficient heat management. Flushing the system regularly prevents blockages and maintains water flow.

Using non-corrosive cleaning agents preserves material integrity. Soft brushes help remove surface contaminants. Proper cleaning methods protect pipes from long-term damage and performance loss.

External heat sources accelerate wear. PPR-Rohrschelle helps secure pipes away from direct heat exposure. Placing pipes in shaded areas reduces thermal stress.

Heat-reflective coatings provide additional protection. Avoiding installation near high-temperature equipment prevents overheating. Proper environmental considerations extend pipe longevity and maintain efficiency.

Maintaining heat-resistant PPR pipes requires correct installation, regular inspections, and protective measures. PPR-Rohrschelle stabilises pipes, preventing heat-induced stress and deformation.

Using high-quality materials ensures durability. Cleaning and monitoring temperature levels improve long-term performance. Following these practices guarantees a reliable and efficient piping system.

IFAN-Produkte halten sich strikt an eine umfassende Palette internationaler Standards, darunter ISO 15874, EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, NBR 15884, ISO 15494, EN ISO 15494, GB/T 19472, NBR 15494, ASTM 2846 (501), DIN 8079/8080 (502), ASTM F441/F441M SCH80 (503), DIN (504), DIN (505), GB/T 18993, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, TIS 17-2532/1131-2535, BS 3505, BS 4346 (801), ASTM D1785 SCH40 (802), ASTM D1785 SCH80 (803), DIN (804), GB (805), GB (806), GB(901), DWV(902), ASTM D2665 (903), zusammen mit ASTM D2241, D2665, D2729 und F441/F441M-Serie, ISO 1452, EN ISO 1452, DIN 8061/8062, GB/T 10002, AS/NZS 1477, JIS K6741, CSA B137.3 und anderen nationalen und Industrienormen.ab und erfüllen so umfassend die strengen globalen Anforderungen an qualitativ hochwertige Produkte.

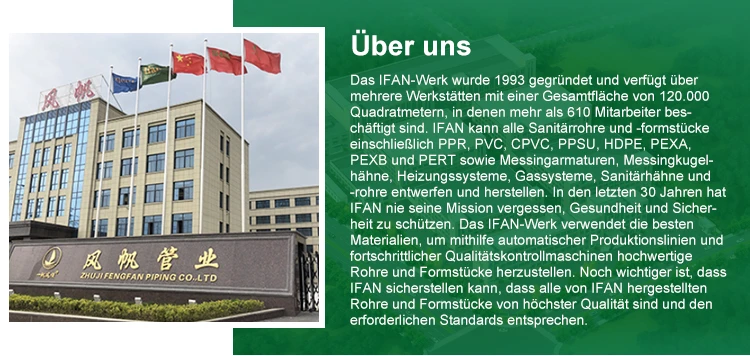

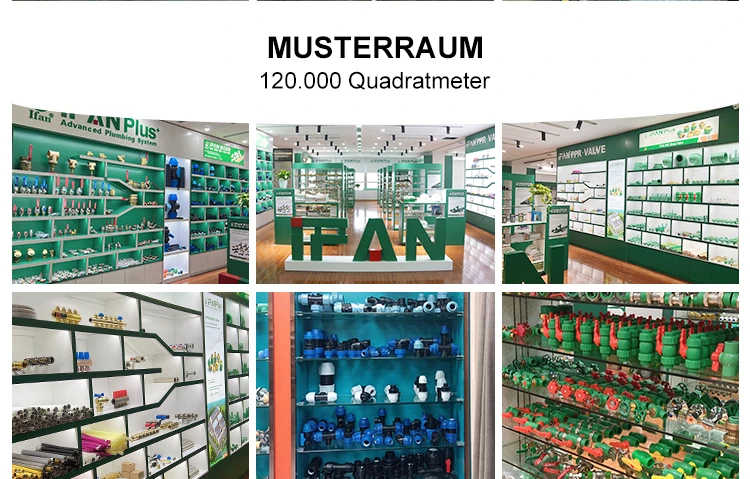

IFAN ist ein chinesischer Hersteller von Kunststoffrohren, -armaturen und -ventilen mit 30 Jahren Erfahrung. Wenn Sie an Kupferarmaturen, Kupferventilen, Kunststoffrohren und -armaturen von IFAN interessiert sind, kontaktieren Sie uns bitte. IFAN bietet Ihnen eine Vielzahl von Standardrohren, um Ihren spezifischen Anforderungen gerecht zu werden. Klicken Sie unten, um mehr über IFANs breites Angebot an erschwinglichen und kosteneffektiven Ventilprodukten und Produkten für Rohrleitungssysteme zu erfahren.

Wir werden Ihre E-Mail oder Ihr Fax innerhalb von 24 Stunden beantworten.

Sie können uns jederzeit anrufen, wenn Sie Fragen zu unserer Produktion haben.

Weitere Informationen finden Sie auf unserer Website https://ifanplus.de/

Bitte senden Sie eine E-Mail an: [email protected]

Stellen Sie ein detailliertes Produktangebotsformular und kostenlose Muster zur Verfügung