CN Household Pipe Fittings Manufacturing Group

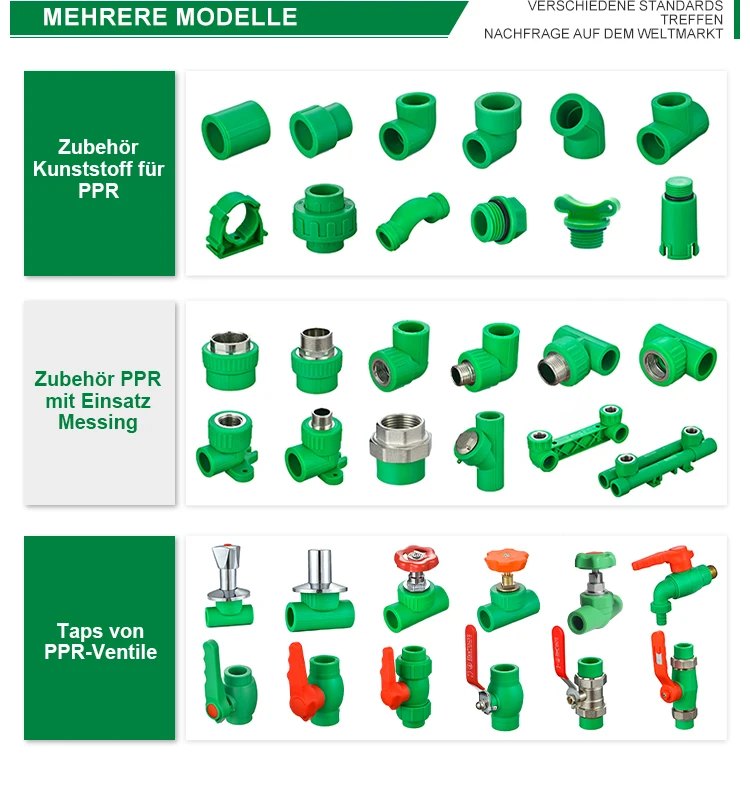

Produktname: PPR-Rohrverbindungen

Material: Korea Hyosung-Rohmaterial

Farbe: Grün/Weiß/Gelb/Grau/Blau/Kundenspezifisch

Größe: 20–110 mm

Verpackung: Opp-Beutel + Karton oder kundenspezifisch

Verbindung: Schweißen

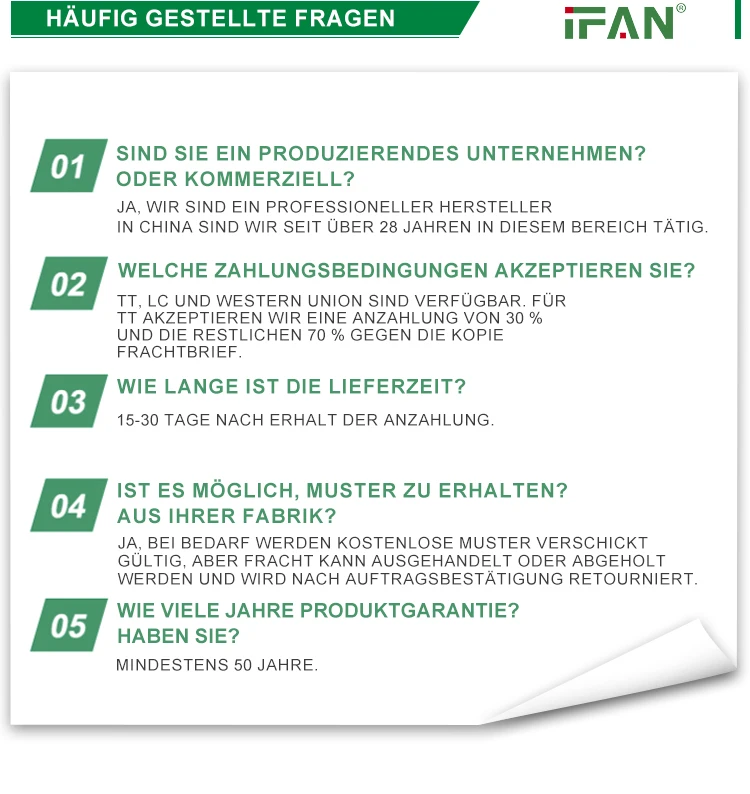

Garantiezeit: 50 Jahre

Lieferhafen: Ningbo, Yiwu, Shanghai

Muster: Kontaktieren Sie uns für ein kostenloses Muster

Senden Sie das Formular, um sofort eine Produktpreisliste und kostenlose Muster zu erhalten

Proper maintenance of PPR Doppel Innenwinkelstück ensures a reliable piping system. Over time, joints experience wear due to pressure and temperature changes. Neglecting maintenance leads to leaks and inefficiencies.

Well-maintained joints provide a strong connection between pipes. Poorly maintained joints reduce water pressure and increase the risk of structural damage. Regular inspection helps detect early signs of wear and prevents costly repairs.

Several factors cause problems in PPR pipe joints. High water pressure may weaken the connections. Frequent temperature fluctuations also affect joint stability.

Cracks and deformations occur due to improper installation or external stress. Additionally, dirt and mineral deposits accumulate inside joints, restricting water flow. Addressing these issues promptly ensures efficient system performance.

Regular inspections keep PPR Doppel Innenwinkelstück in optimal condition. Checking for visible cracks or leaks helps detect potential failures. Pressure testing ensures joint integrity under operational conditions.

Using thermal imaging detects temperature inconsistencies in joints. Listening for unusual noises in the piping system helps identify hidden issues. Scheduled inspections prevent major failures and extend the system’s lifespan.

Dirt and mineral deposits reduce joint efficiency. Cleaning PPR Doppel Innenwinkelstück prevents blockages and improves water flow. Flushing with clean water removes loose debris.

For stubborn deposits, specialised cleaning agents dissolve mineral build-up. Soft-bristle brushes help clean joint surfaces without causing damage. Regular cleaning prevents long-term performance issues.

Small cracks or leaks in PPR Doppel Innenwinkelstück require immediate repair. Using a sealant temporarily stops minor leaks. However, long-term solutions involve replacing damaged joints.

Cutting out the affected joint and installing a new one ensures a secure connection. Proper welding techniques prevent future leaks. Ensuring correct alignment during installation maintains optimal performance.

Replacing joints becomes necessary when repairs are no longer effective. Persistent leaks indicate severe joint deterioration. Discolouration or deformation suggests material degradation.

Frequent pressure drops signal internal damage. If cleaning fails to restore efficiency, replacing the joint ensures smooth operation. Using high-quality replacement joints improves system longevity.

Proper installation of PPR Doppel Innenwinkelstück prevents future maintenance issues. Aligning joints correctly avoids stress points. Applying the right amount of heat during welding ensures a strong bond.

Avoiding excessive pressure during connection prevents deformations. Using compatible fittings enhances durability. Following manufacturer guidelines guarantees a secure and long-lasting joint installation.

Maintaining and replacing PPR Doppel Innenwinkelstück ensures an efficient piping system. Regular inspections detect early issues. Cleaning prevents blockages, and timely repairs avoid major failures.

Knowing when to replace joints prevents costly damage. Proper installation techniques extend the lifespan of joints. Following these steps ensures reliable water flow and long-term pipe performance.

IFAN-Produkte halten sich strikt an eine umfassende Palette internationaler Standards, darunter ISO 15874, EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, NBR 15884, ISO 15494, EN ISO 15494, GB/T 19472, NBR 15494, ASTM 2846 (501), DIN 8079/8080 (502), ASTM F441/F441M SCH80 (503), DIN (504), DIN (505), GB/T 18993, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, TIS 17-2532/1131-2535, BS 3505, BS 4346 (801), ASTM D1785 SCH40 (802), ASTM D1785 SCH80 (803), DIN (804), GB (805), GB (806), GB(901), DWV(902), ASTM D2665 (903), zusammen mit ASTM D2241, D2665, D2729 und F441/F441M-Serie, ISO 1452, EN ISO 1452, DIN 8061/8062, GB/T 10002, AS/NZS 1477, JIS K6741, CSA B137.3 und anderen nationalen und Industrienormen.ab und erfüllen so umfassend die strengen globalen Anforderungen an qualitativ hochwertige Produkte.

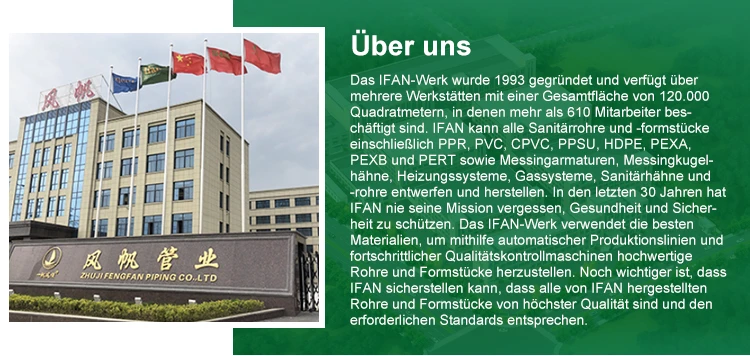

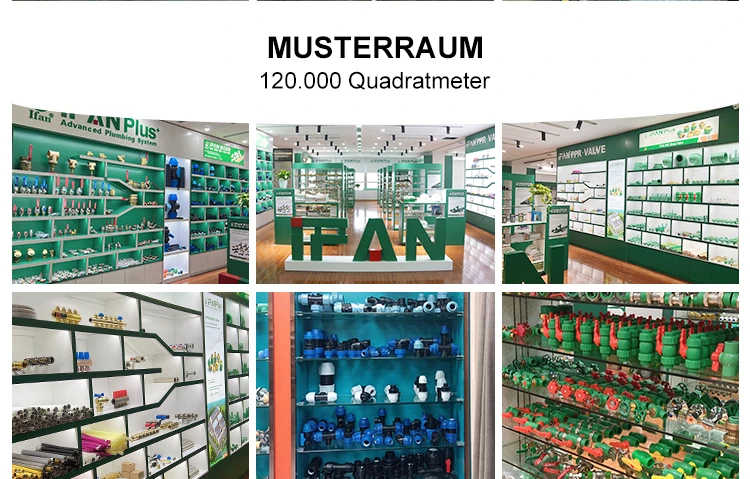

IFAN ist ein chinesischer Hersteller von Kunststoffrohren, -armaturen und -ventilen mit 30 Jahren Erfahrung. Wenn Sie an Kupferarmaturen, Kupferventilen, Kunststoffrohren und -armaturen von IFAN interessiert sind, kontaktieren Sie uns bitte. IFAN bietet Ihnen eine Vielzahl von Standardrohren, um Ihren spezifischen Anforderungen gerecht zu werden. Klicken Sie unten, um mehr über IFANs breites Angebot an erschwinglichen und kosteneffektiven Ventilprodukten und Produkten für Rohrleitungssysteme zu erfahren.

Wir werden Ihre E-Mail oder Ihr Fax innerhalb von 24 Stunden beantworten.

Sie können uns jederzeit anrufen, wenn Sie Fragen zu unserer Produktion haben.

Weitere Informationen finden Sie auf unserer Website https://ifanplus.de/

Bitte senden Sie eine E-Mail an: [email protected]

Stellen Sie ein detailliertes Produktangebotsformular und kostenlose Muster zur Verfügung