CN Household Pipe Fittings Manufacturing Group

Produktname: PPR-Rohrverbindungen

Material: Korea Hyosung-Rohmaterial

Farbe: Grün/Weiß/Gelb/Grau/Blau/Kundenspezifisch

Größe: 20–110 mm

Verpackung: Opp-Beutel + Karton oder kundenspezifisch

Verbindung: Schweißen

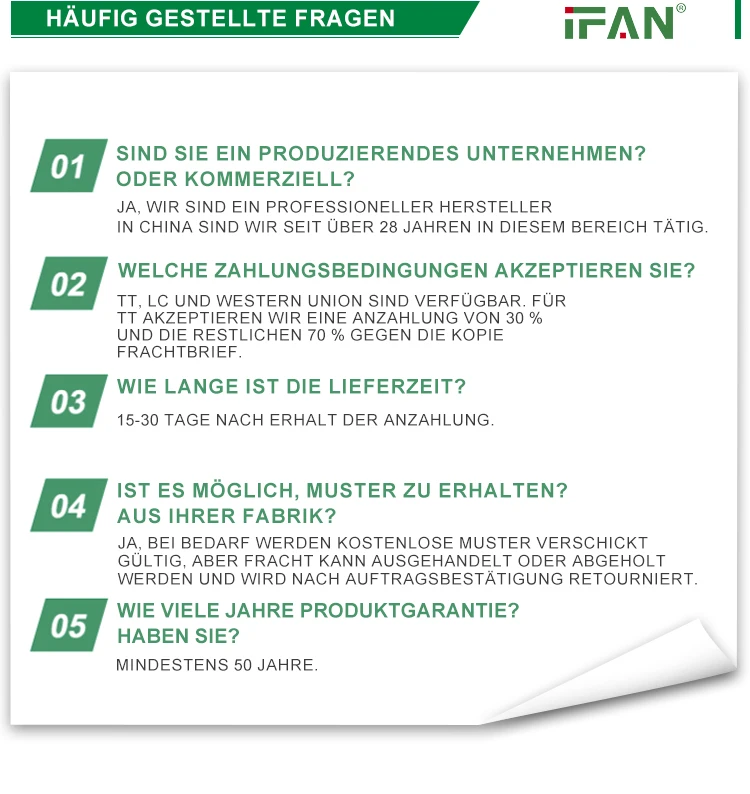

Garantiezeit: 50 Jahre

Lieferhafen: Ningbo, Yiwu, Shanghai

Muster: Kontaktieren Sie uns für ein kostenloses Muster

Senden Sie das Formular, um sofort eine Produktpreisliste und kostenlose Muster zu erhalten

Efficient Cleaning of the Interior of PPR Pipes

Cleaning PPR-Steady-State-Röhrchen ensures efficient water flow and prevents contamination. Over time, dirt and mineral deposits accumulate inside pipes. Regular maintenance extends the lifespan of pipes and prevents blockages. Unclean pipes may also develop bacteria, affecting water quality.

Clean pipes improve overall system efficiency. Poorly maintained PPR-Steady-State-Röhrchen reduce water pressure and increase energy consumption. For industrial and domestic applications, proper cleaning guarantees hygiene and safety. Therefore, regular pipe maintenance is necessary for long-term functionality.

Several contaminants affect PPR-Steady-State-Röhrchen. These include mineral deposits, rust, biofilm, and debris. Hard water deposits, such as calcium and magnesium, can cause blockages. If left untreated, they reduce pipe efficiency.

Biofilm formation is another issue. It consists of bacteria and microorganisms that cling to the pipe walls. In water supply systems, biofilm can cause health hazards. Dirt and external particles may also enter the pipes during installation or repairs. Proper cleaning methods remove these contaminants effectively.

Mechanical cleaning removes dirt and debris using physical force. This method suits heavily clogged PPR-Steady-State-Röhrchen. One technique involves using pipe-cleaning brushes to scrub the interior surface. These brushes remove deposits without damaging the pipes.

Another mechanical method is the use of high-pressure water jets. These jets flush out accumulated particles and maintain water flow efficiency. In some cases, cleaning pigs are used. These flexible tools travel through the pipes, pushing contaminants out. Mechanical cleaning is effective but should be combined with other methods for better results.

Chemical cleaning dissolves stubborn deposits inside PPR-Steady-State-Röhrchen. Specialised cleaning agents break down calcium, rust, and organic matter. These solutions flow through the pipes, removing internal build-up.

However, choosing the right cleaning agent is crucial. Harsh chemicals may damage PPR materials or leave harmful residues. Eco-friendly and biodegradable solutions are safer alternatives. After chemical cleaning, thorough rinsing ensures no chemical traces remain. This prevents contamination and maintains pipe integrity.

Flushing is an essential step in cleaning PPR-Steady-State-Röhrchen. High-speed water flow removes loose debris and chemical residues. Proper flushing guarantees clean and safe pipes.

Several flushing techniques exist. One common method is unidirectional flushing, where water flows in one direction, pushing contaminants out. Another approach is pulse flushing, which uses intermittent bursts of water to dislodge particles. These techniques maintain optimal pipe performance and hygiene.

Regular maintenance prevents major contamination issues in PPR-Steady-State-Röhrchen. Scheduled inspections help identify potential problems before they worsen. Implementing filtration systems at water inlets reduces debris entry.

Another preventive measure is maintaining stable water pressure. Fluctuations can cause deposits to accumulate unevenly. Additionally, using water softeners minimises mineral build-up, prolonging pipe lifespan. Proper maintenance reduces the need for frequent deep cleaning.

Following industry best practices ensures effective PPR-Steady-State-Röhrchen cleaning. Professionals recommend a combination of mechanical, chemical, and flushing techniques. Using appropriate tools and cleaning agents prevents pipe damage.

Regular water quality testing detects early signs of contamination. Adhering to manufacturer guidelines also helps maintain pipe integrity. Additionally, trained personnel should handle cleaning procedures to avoid improper techniques. Industry standards guarantee safe and efficient pipe maintenance.

Efficient cleaning of PPR-Steady-State-Röhrchen improves performance and longevity. Contaminants such as mineral deposits, biofilm, and debris affect pipe efficiency. Mechanical, chemical, and flushing methods ensure thorough cleaning.

Preventive maintenance strategies reduce contamination risks. Adopting industry best practices enhances cleaning effectiveness. Clean pipes provide better water flow, hygiene, and durability. Regular inspections and proper cleaning techniques ensure optimal PPR pipe performance.

IFAN-Produkte halten sich strikt an eine umfassende Palette internationaler Standards, darunter ISO 15874, EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, NBR 15884, ISO 15494, EN ISO 15494, GB/T 19472, NBR 15494, ASTM 2846 (501), DIN 8079/8080 (502), ASTM F441/F441M SCH80 (503), DIN (504), DIN (505), GB/T 18993, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, TIS 17-2532/1131-2535, BS 3505, BS 4346 (801), ASTM D1785 SCH40 (802), ASTM D1785 SCH80 (803), DIN (804), GB (805), GB (806), GB(901), DWV(902), ASTM D2665 (903), zusammen mit ASTM D2241, D2665, D2729 und F441/F441M-Serie, ISO 1452, EN ISO 1452, DIN 8061/8062, GB/T 10002, AS/NZS 1477, JIS K6741, CSA B137.3 und anderen nationalen und Industrienormen.ab und erfüllen so umfassend die strengen globalen Anforderungen an qualitativ hochwertige Produkte.

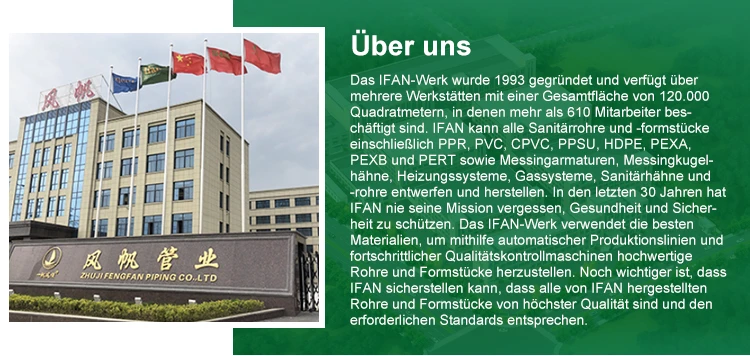

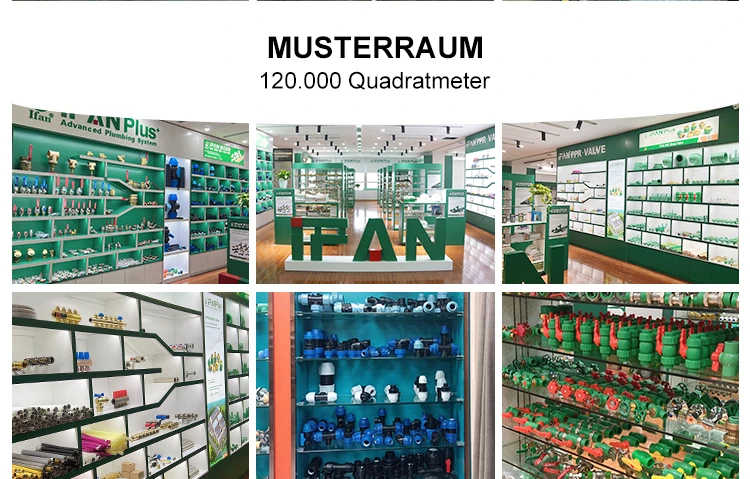

IFAN ist ein chinesischer Hersteller von Kunststoffrohren, -armaturen und -ventilen mit 30 Jahren Erfahrung. Wenn Sie an Kupferarmaturen, Kupferventilen, Kunststoffrohren und -armaturen von IFAN interessiert sind, kontaktieren Sie uns bitte. IFAN bietet Ihnen eine Vielzahl von Standardrohren, um Ihren spezifischen Anforderungen gerecht zu werden. Klicken Sie unten, um mehr über IFANs breites Angebot an erschwinglichen und kosteneffektiven Ventilprodukten und Produkten für Rohrleitungssysteme zu erfahren.

Wir werden Ihre E-Mail oder Ihr Fax innerhalb von 24 Stunden beantworten.

Sie können uns jederzeit anrufen, wenn Sie Fragen zu unserer Produktion haben.

Weitere Informationen finden Sie auf unserer Website https://ifanplus.de/

Bitte senden Sie eine E-Mail an: [email protected]

Stellen Sie ein detailliertes Produktangebotsformular und kostenlose Muster zur Verfügung